|

Indications from ash

Green Indicator is a newsletter with the purpose of holding up a finger and feeling the direction of current winds within the world of renewable chemical industry. Lately, the winds of Northern Europe have brought with them something small and hardly noticeable but still with tremendous impact on the infrastructure we have created. Icelandic ash has not only grounded thousands of European flights but has hopefully also given us an early tutorial on how to cope without sufficient supplies of oil-based fuels. We have taken quick, relatively cheap transport for granted for a long time but everyone should agree that this cannot continue without a serious effort from people and governments.

But other than leaving tens of thousands of Europeans stranded in destinations across the continent and raising the awareness of alternative transit systems, what has Eyjafjallajökull done for us? It has spared us 200 000 tons of CO2. Daily. The feeling is perhaps that an unfiltered king size smoke stack like a volcano would contribute to more GHG gases than a couple of airplanes, but research by David McCandless and Ben Bartels at Information is Beautiful shows the contrary. Using information from mostly well-known sources, they have calculated the daily CO2 emissions from European Aviation to 344 000 tons, whereas the same figure for Eyjafjallajökull is 150 000 tons. The avoided CO2 emissions as a result by 60% cancelled flights across Europe are thus approximately 200 000 tons per day.

Volcanoes could also cause global cooling. Scientists following the events of the 1991 eruption of the Philippinean volcano Mt Pinatubo also claim that the vast release of SO2 and particles reduced the global average temperature of 0.5 oC. (Source)

So despite irritation over a week of cancellations and changed plans, perhaps the Eyjafjallajökull eruption did us a favour in the long-term. It made many of us think twice when planning our next trip. How much can you take for granted?

/ Christian Hulteberg

The Answer

What do you percieve to be the major obstacle to commercializing non-fossil based fuels?

given by Lars Stigsson, owner and founder of KIRAM

The only way to increase the portion of non-fossil fuels in the automotive sector at present is to further increase taxes on greenhouse gases emitting fuels. The taxes thus obtained should at least partly be used to support green fuel demonstration plants and the development of more efficient engines.

What drives development?

How are you to know what is a good, sustainable business case in an ever changing world? How will my target market develop over time? Are there hidden snags that we have overlooked? These are questions that we all ponder when entering into a new area of development and there is no short answer. But there may be ways to leverage your risk. This piece of writing will give an example of how global factors can influence the development of a chemical process, butanol fermentation (ABE-fermentation), it will also suggest a combination of methods on how to lower the risk in the development of new processes and products.

The discovery that some bacteria could produce butanol was discovered at the end of the 19th century; about the same time there was a worldwide shortage of natural rubber, resulting in the Strange and Graham, Ltd. process for synthesizing rubber from butanol. The process was based on an anaerobic fermentation process and the bacterium used was later identified as Clostridium acetobutylicum, producing significant amounts of side-products such as acetone and ethanol (ratios 6:3:1 butanol, acetone and ethanol). The first industrial plant was commissioned in 1913 and it was closed later the same year due to expansion.

The development took a new turn with the First World War, which drove the demand for Cordite (smokeless gun powder). The production of Cordite requires acetone and production of acetone using ABE-fermentation expanded rapidly in the UK and the US. However, since there was basically no demand for butanol during the war, it was stored until the war ended and thereafter sold. One of the applications for the large amount of stored butanol was the volatile paints used in the up-and-coming car industry and the production capacity was increased in the 1920-ies. However already in the 1930-ies, mineral-oil based acetone and butanol was identified as a threat to the fermentation industry and the production was in decline.

Nonetheless the production was increased again during the Second World War as ammunition was again in high demand and a number of ethanol plants were converted to ABE-fermentation. After the end of the Second World War, the production declined due both to competition from mineral-oil based processes and to increasing prices on molasses, used as feedstock in the fermentation. From the 1960-ies, no butanol was produced using this method in the Western world. In the Soviet Union, China and South Africa production continued into the 1980-ies and in China 50% of the acetone produced is still fermentation based. This could have been the end of the ABE-fermentation saga, but in the early years of the 21st century, several initiatives were taken to renew the production of butanol with the method. Among those the joint venture between BP and DuPont, with a planned full scale plant in 2010, and the Virgin Green Fund and Khosla Ventures investment into the start-up company Gevo Development LLC can be mentioned. The driving force behind this was mainly the identification of butanol as a suitable replacement for gasoline and jet kerosene from a non-fossil source.

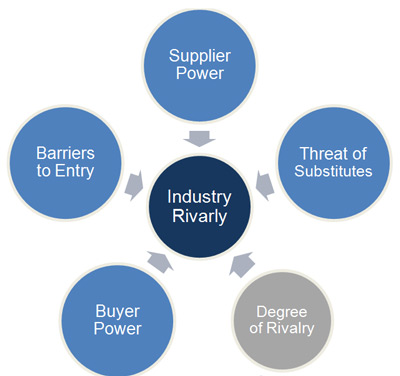

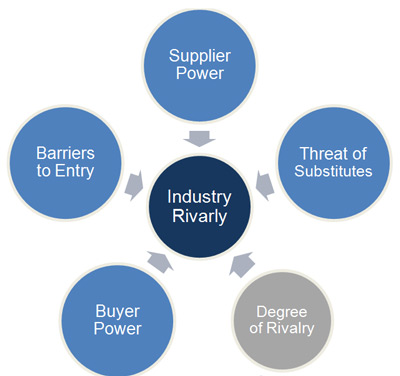

As can be seen from the above example, process development can be difficult to predict and global factors play a significant part in the incentives behind the development of a process. How does one then try to lower the risk when faced with a similar situation? A useful method is a combination of the Five Forces model and scenario analysis.

By constructing various scenarios of the future, the impact of different future global events can be somehow predicted. However by implementing the Five Forces model to characterise the competitive environment in each conceivable future the competitiveness can be qualitatively estimated.

In this way the competitive environment in several future situations can be viewed and most known unknown factors investigated. And who knows - perhaps some of the scenarios may also be applicable for other unknown factors.

|