|

Increased revenue through biomass refining

Greetings, in this edition of Green Indicator we will have a closer look on one of the few existing, commercial biorefineries in operation today, namely the pulp and paper industry. This is an industry with very long experience of handling, processing and upgrading huge quantities of biomass. However, as the name alludes to, the industry has the primary focus of putting out paper, or pulp for that matter, in various types and qualities but no other products. Compare this to another mature industry: the refining of mineral oil. In this industry every last drop of oil is taken care of and hundreds, if not thousands, of different products produced from the starting material; and it’s not always the largest streams of e.g. petrol or diesel that contribute the most to the actual revenue. In this edition of the Green Indicator, we will have a closer look at the various side-product streams from the paper/pulp industry to see if there is potential for getting more out of the bottom of the biorefinery barrel.

/ Christian Hulteberg

The Answer

What do you percieve to be the major obstacle to commercializing non-fossil based fuels?

given by Rahul Iyer, President at Golden Bridge Strategies

The informed consumer is critical to the function of any market, and energy is no exception. It can be argued that our woefully unsustainable energy industry relies on an ill-informed consuming public to sustain its profitable existence. The broad commercialization of non-fossil based fuels requires a permanent shift in the perception of energy by energy consumers. Consumers must become aware of energy supply chains and the costs and benefits associated with the various links in these chains (a life-cycle perspective). When equipped with a more durable understanding of our current energy system (eg well-to-wheel), consumers will be less susceptible to ‘the buzz’ or ‘flavor of the month’ energy problems/solutions. The informed consumer will ultimately provide both the clear price signals required for long-term development and investment in non-fossil fuels, and the public support required for a new generation of energy regulations.

Progress for hemicellulose

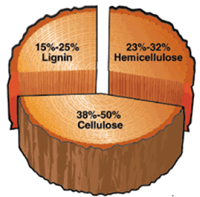

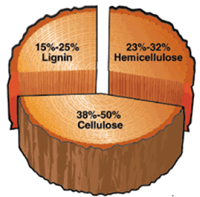

Your typical wood will contain 38-50% cellulose, 15-25% lignin and 23-32% hemicelluloses. The hemicelluloses will during the processing to paper and pulp end up in soluble water fractions such as process water and waste water in the form of:

- Xyloglycans

- Beta-glucans

- Mannans

- Xylans

These soluble molecules/sugars can be processed to various added-value chemicals. One alternative is to ferment the sugars into a number of different chemicals; one being ethanol from which acetaldehyde, acetic acid, ethyl acetate as well as vinyl acetate and poly-vinyl acetates can be synthesised. Another new development at the Royal Institute of Technology in Stockholm includes the production of hydrogels from the hydrolysed hemicelluloses. These hydrogels are excellent at absorbing water and can be used e.g. in diapers as well as in coatings and films. There is also the potential for other fermentation processes, including succinic (or amber) acid, a target molecule by many of the larger chemical production companies today including BASF and Mitsubishi Chemicals. Any of these additional revenues will provide helpful in improving the competitiveness of the industry, as well as contributing significantly to a future where equal living standards can be achieved without mineral oils.

Lignin requires innovation

There is an old saying that “you can do anything from lignin but money”. We however think that even though there may be some truth to this, lignin is a starting material with good potential. In the traditional paper/pulp mill the lignin is burnt in the chemical recovery and thus produces energy. With the advent of new technology, including the LignoBoost (developed by STFI Packforsk/Chalmers University of Technology and now owned by Metso), there will be a lot of available lignin on the market. The lignin origin is however of importance as different sources produce very different lignin qualities. There are a lot of suggested end-products for lignin with phenols being one of the few products actually in commercial production from lignin, albeit unable to compete with the cheap petroleum based phenols. Other products in commercial production e.g. by Børregaard include vanillin, acetovanillon, lignosulphonates and veratric acid. Other suggestions on chemicals include:

- Binders (produced using phenols and formaldehyde)

- Carbon fibre

- Activated carbon

- Carbon black

All of the above, except perhaps activated carbon, is probably best produced off-site in an integrated chemistry complex. There is however a lot of room for innovation in this area and with ever increasing mineral oil costs, chemicals based on green chemistry will become more competitive. The additional availability of lignin will also drive the development in this area and we are sure that the first sentence in this article will be proven wrong in the next couple of years.

|